Innovating Sustainable Footwear Manufacturing

ZQY, a Taiwan based company with international partnerships, leverages its unmatched science and innovation to solve complex challenges for customers, drive sustainable and measurable results and help communities and businesses around the world move cleaner, create smarter and live better every day.

Founded in 2017, ZQY owns and operates shoe manufacturing facilities, technology and digitalization task teams, ESG and Carbon management strategic team in Taiwan and partnerships around the world.

Core Values

Our Core Values

Innovation

We strive to innovate and create sustainable solutions that drive positive change in the footwear industry.

Efficiency

We believe in optimizing production processes and reducing waste to maximize efficiency and minimize environmental impact.

Collaboration

We collaborate with partners to achieve shared goals of carbon reduction and sustainability.

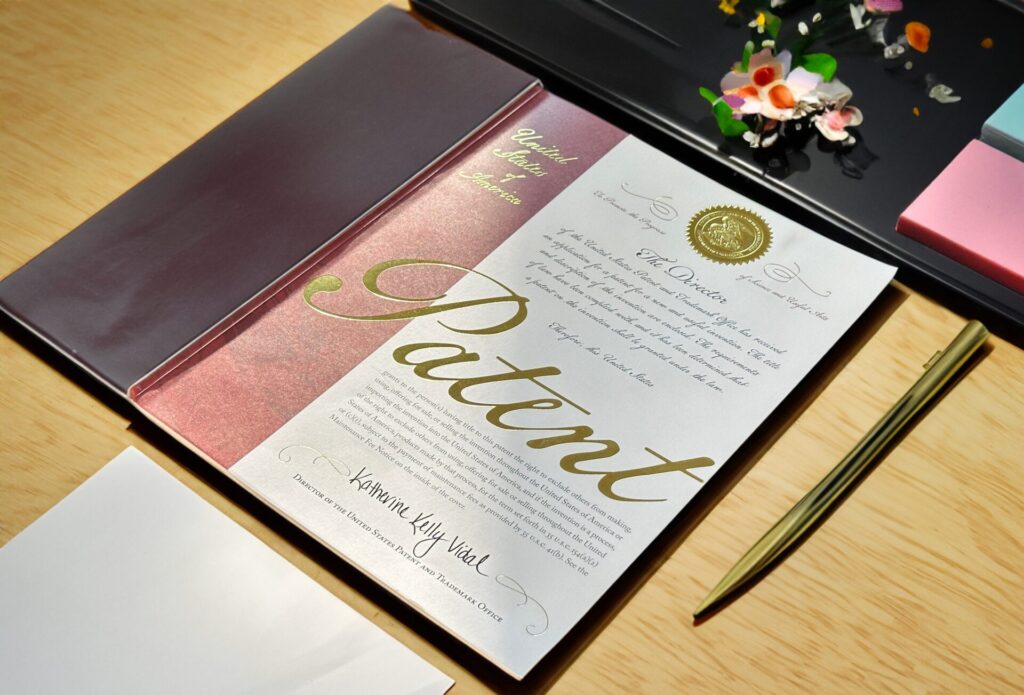

In contrast to traditional footwear products made with mixed materials, ZQY patented technology (US Patent Number US11691371 B2) helps enhance circularity by being composed of one core material; demonstrating a combination of ZQY’s advanced TPU solutions for footwear that work together to enable simplified production through improved compatibility between parts. TPU materials also allow for in-mold adhesion during the shoe soling process, which can increase automation and efficiency, while reducing multiple gluing processes. The patented process is evidenced to reduce up to 70% of labor and related carbon footprint.

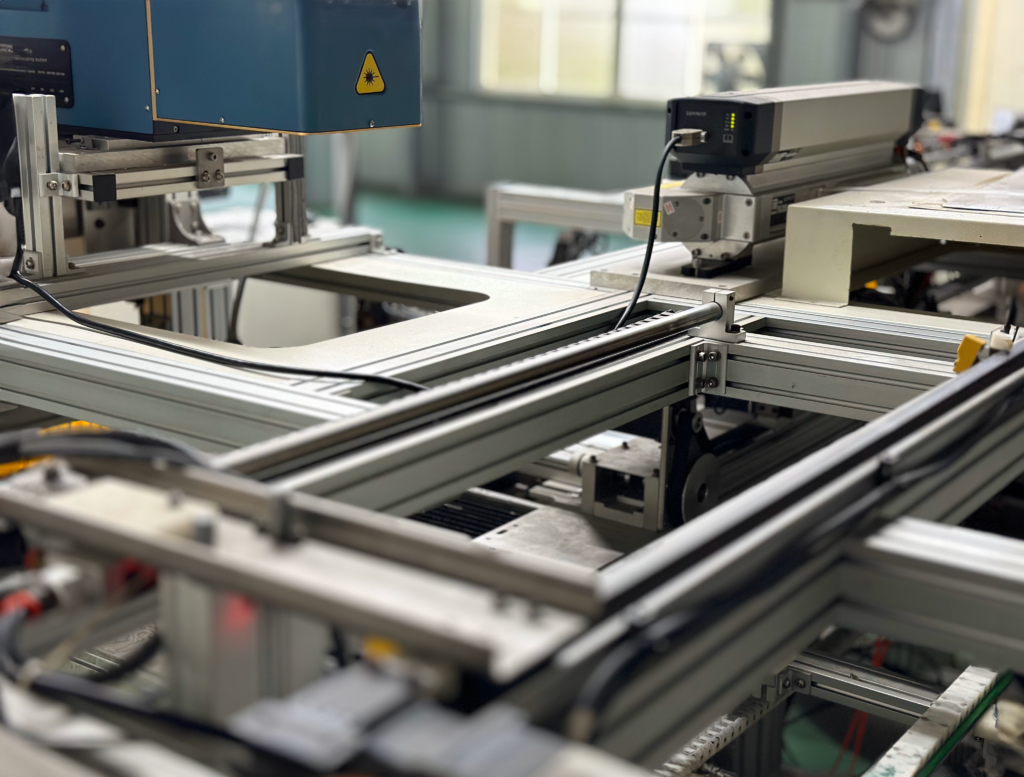

In consideration of the high-mix, low-volume production model typical of the shoe manufacturing industry, ZQY cooperated with a major shoe manufacturing machine maker to build a smart machine management solution that integrates intelligent software and hardware technologies.

Three major trends have emerged in the machinery industry in recent years — the standardization of power generation and carbon reduction, the serviceability of products and solutions, and smart manufacturing equipment. In response to these trends, the shoe-making machinery industry must accelerate its smart transformation to enhance its competitiveness. Accordingly, ZQY collaborated with machine maker to deploy Smart Machine Solution Platform (SMSP) that leverages ZQY’s expertise in smart manufacturing, machine networking, and AI edge computing for smart machine management.

Hardware Solutions

In terms of hardware, the shoe manufacturing machine maker adopted ZQY’s cloud based real-time monitoring gateway for collecting machine data to facilitate operations monitoring. This real time cloud based platform enables managers to troubleshoot problems in real-time and provided a function that solved a long-existing data integration problem caused by machines using different communication protocols and data formats. Now, with the standardization of equipment and sensor data, factory managers can monitor every machine from their app dashboard.

Software Solutions

In terms of software, the Smart Machine Solution Platform (SMSP) adopted by the machine maker can be integrated with ZQY’s cloud platform and combined with value-added industrial apps, including the Overall Equipment Effectiveness (OEE), Repair Management Service, and Event, Alarm, and Notification applications. All of these tools have enabled the machine maker to digitally upgrade its machine-making facilities and provide for future decarbonization journey.